The Turpentine Industry in Alabama

The Turpentine Industry in Alabama is one of the least known facts about the state, and most young people today have never heard of it.

However, it was once a thriving, profitable, dangerous, and very threatening industry, and has left its mark on the forests in this beautiful state.

It you are in the woods and happen to walk across a “cat face” tree, most people today would never give it much of second thought.

With the disfigured and scarred truck, you would simply think it was struck by lightning, or was the result of some type of tree disease.

However, these “scarred” trees or what remains of them, are tell-tell signs of our ancestors search for pinesap and the flammable oil it produced, as well as its use in soap, ink, lubricants, and many other products.

The Turpentine Industry in Alabama belongs for the most part to a bygone era, but during this era, it left an indelible mark not only on the trunks of trees, but dead forests in several of the state’s counties.

Created by the distillation of tree resign, turpentine was mostly derived from pine trees, and gets its somewhat infamous name from the Greek word “terebinthine”.

This is also the name of a Mediterranean tree related to the pistachio, which was perhaps its earliest source.

The southern part of the state, which has numerous acres of pine trees, was the most appealing to its producers, especially in the following counties.

These counties included Baldwin, Mobile, Washington, Choctaw, Escambia, as well as Tuscaloosa.

The Turpentine Industry in Alabama thrived between 1840 and 1930, and when paired up with the Port of Mobile, it exploded as many of the byproducts were critical in shipbuilding at the time.

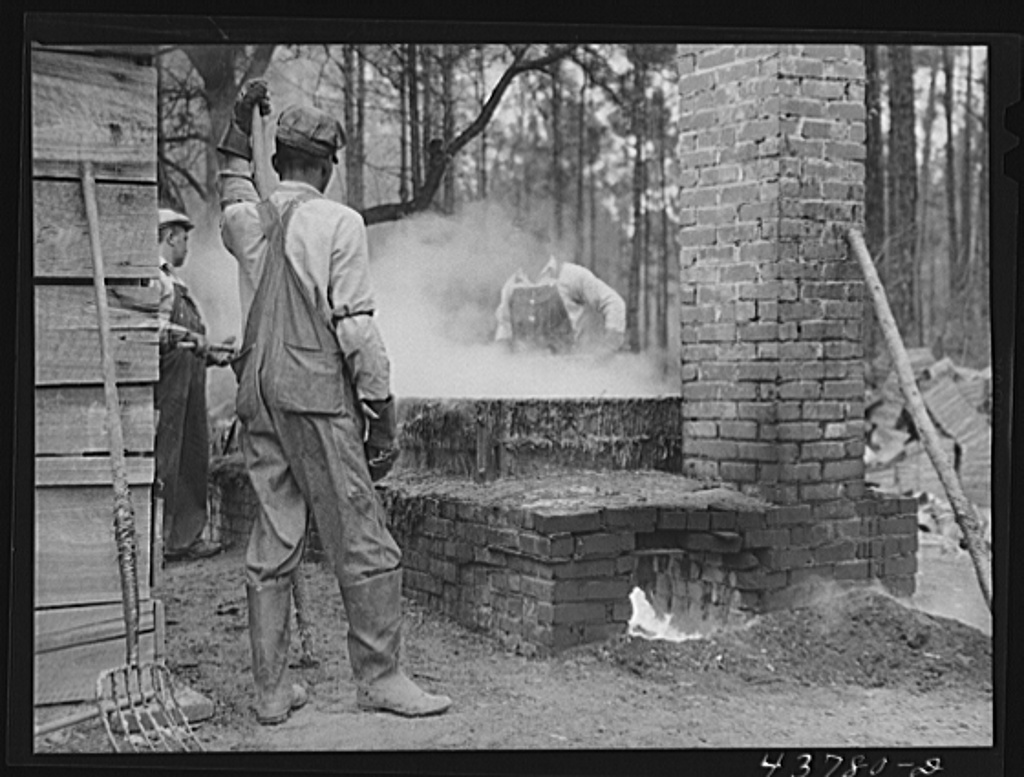

Men Working In the Turpentine Industry

Men Working In the Turpentine IndustryThe History of the Turpentine Industry in Alabama

The longleaf pine forest that at one time covered most of the state provided ample supplies for this industry.

It had many uses, by its primary use was as a solvent for fuel, resign in soap, as well as the varnish industries, especially related to shipbuilding.

The industry that produced it was also known by the name “Naval Stores”, because the pitch in it was used to caulk the seams of wooden sailing boats which were made from the products of trees.

The early years of the Turpentine Industry in Alabama very quickly became synonymous with several dubious practices, including very questionable labor practices.

The reason for this was simple; several of the companies used “enslaved labor” that exploited both convicts, as well as immigrants.

After slavery was abolished in the state, most men were unwilling to work under the grueling tasks needed to make this product.

Because of this, owners and operators of the Turpentine Industry in Alabama began to lease convicts from the prisons or lure immigrants with false promises of high wages.

Most historians agree that the harvesting of this product began in the 1770’s in Mobile County, but also agree that it did not explode in growth until the 1840’s.

After lightweight copper stills were invented in 1834, these machines reduced the cost of production, as they could be set up near where the trees were harvested.

However, there was another key factor that increased the production, increased consumer demands.

The rubber industry that was also exploding during this same time used turpentine as a solvent, and the exploding soap and varnish industries required the resign it produced.

It was also used by small farmers and sharecroppers as a cheap alternative to lamp oil, also making its demand explode.

In 1847, Col. R.D. James started a small-scale production company in Clarke County, which by the year 1855 was yielding over 1,000,000 gallons of turpentine, as well as about 130,000 barrels of resign each year.

Because of the largely untouched pine forests located in the mentioned southern counties of the state, the Turpentine Industry in Alabama kept growing.

In fact, between the years 1850 and 1860, the economic worth of the related industries in the state increased over 36 times, from $17,800 to $642,000.

The Cleaning Process in The Turpentine Industry

The Cleaning Process in The Turpentine IndustryThe Turpentine Industry in Alabama and Its Changes

The Turpentine Industry in Alabama changed very little from how it started in the 19th century into the 20th century.

Its season, which lasted about eight months, saw its laborers extract the sap from the longleaf pine trees, in a series of three steps.

Generally, they started in November, where the workers would begin the process of “boxing” the trees.

They would use long-headed axes and would basically cut a box into the base of the tree, which would range from 10-14 inches wide and 2.5-3.5 inches deep, and this would allow them to catch the “sap” from the trees

After this step was completed, around March, they would then chip a “streak” that was about 2/3 of an inch wide and 1 inch deep.

They would cut this above the “box” by using a tool called a hack, and this chipping would continue for 32-34 weeks collecting the sap.

Then when April came, the workers would start to use a steel spatula to basically “spoon” the liquid, now referred to as “gum”, in a process called dipping.

The gum would then be placed in buckets, where it was transferred to 40-gallon barrels, where it would be transported to a distillery.

However, this process has two major disadvantages; it was extremely labor intensive, and it would eventually kill the trees.

This is the major reason the Turpentine Industry in Alabama had to move so often to other parts of the state, as they had to find untouched forests.

Most of the owners of these operations that were in Alabama had relocated from North Carolina, where they had already severely damaged the forests.

Turpentine Camps

Turpentine CampsWith the onset of the Civil War, the market conditions suffered as transportation halted most all of the production.

However, once the War ended and new railroads were built, the production of turpentine again took off, but faced many changes.

The end of enslaved labor caused a huge labor shortage, and several distilleries such as the ones in Tuscaloosa and Escambia counties, leased state inmates.

The system they used was called the “debt peonage”, where indebted convicts were forced to work until a debt or loan they owned was paid off.

However, there was another post-war change that affected the Turpentine Industry in Alabama, the emergence of agents or brokers.

Brokerages had played a major role in this industry since the early part of the 19th century, but they increased their presence after the war.

They now not only bought and sold the products this industry produced; they also financed new operations by leasing both forest tracts, as well as furnish supplies and equipment on credit.

However, the Turpentine Industry in Alabama would change yet again, as in 1907 a Chemist named Homer Yaryan developed a new method of harvesting.

With this new method, the extraction of both turpentine and tar from longleaf pine stumps consisted of heating small pieces of wood from the stumps over a gas fire in a glass container called a retort.

After about 20 hours, the rosin was collected from the bottom of the retort, and with this new method along with increased financing, Alabama remained one of the largest producers in the country.

However, by the late 1940’s and early 1950’s, the supply of mature pine stumps had dramatically decreased, making this new method no longer feasible.

Today turpentine is produced primarily from the pulpwood industry, which is a totally different concept.

At the pulpwood plants, pine trunks are first stripped and then chipped and stewed in sulfuric acid, to separate the cellulose from the rest of the wood.

In addition to the cellulose, this new process also produces turpentine spirits and tall oil, which is a form of rosin that is used in papermaking and a drying agent in paint.

The Turpentine Industry in Alabama still exists but is basically a bygone industry of the past.

References

http://www.encyclopediaofalabama.org/article/h-3137

Little Known Facts About Alabama

Alabama Gift Store

Numerous Items for You and Your Family to Enjoy

See it here at the Gift Store

Copyright 2019-2023 Alabamabackroads.com

All Rights Reserved