Coal In Alabama Is Among the Best in The World

Coal in Alabama in today’s world is not a well-known fact to most of its residents, but it is still a very large and important industry.

What is also not well known about this abundant natural resource is what it has done for this state and its history.

This industry was so important that it literally changed the face of the state in five very distinctive ways.

It changed it geographically, socially, politically, and more important, economically and culturally.

Coal in Alabama still has a huge impact on the state as it still employs over 3,000 people, and generates a whopping $370 million dollars in annual payroll.

In fact, the average employee in this industry makes much more than the average person, as the average salary is over $100,000 a year.

They are considered to be the highest-paid positions in the state, and it runs 1.6 times higher than the average worker wages.

The state is also blessed with ample reserves of this natural resource, as it is estimated that it has over 300 years of reserves in the ground still to be mined.

This fact alone makes it an industry that will help the residents of the state for generations, which again, is not a well-known fact.

While coal in general is thought to be a heat generating natural resource, Coal in Alabama is much different in nature.

It is estimated that over 85% of this natural resource found here is considered to be metallurgical, and as a result, it is used to make steel.

The remaining 15% is considered thermal, which is used to produce electricity.

There are still three more little known facts about this natural resource that are quite shocking to most people.

The first fact is that the Coal in Alabama is considered to be some of the highest quality for steel making in the world, and second, because of this, it exports this resource to Asia, Europe, as well as South America.

The third fact is that it is the largest export through the Port of Mobile, which is the nation’s fourth largest shipper of coal products.

Because of this fact, over 50% of the total revenue that is earned annually by the Alabama State Port Authority is from this natural resource.

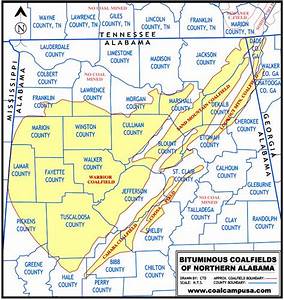

Map of Alabama Coal Fields

Map of Alabama Coal FieldsThe History of Coal in Alabama

Coal is Alabama has a very long and rich history, and over the years has affected the lives of thousands of people in the northern and central part of this historic state.

This natural resource helped to shift the state’s economy beyond its traditional agricultural base, and was estimated to have been first discovered here in the year 1815.

About 15 years later, early accounts have suggested that several citizens from five different counties in the state started collecting the natural resource, as early as the 1830’s.

In the 1840’s, geologists, mining engineers, as well as businessmen discovered four different fields of this abundant natural resource.

These four fields included the Warrior, the Cahaba, the Coosa, as well as the Plateau Fields, and once this discovery was made, Coal in Alabama began to take off.

Historical summaries of this industry suggest that the first systematic underground mining occurred in the Cahaba Field, in the year 1856.

However, most experts agree that the Alabama Coal Mining Company, also known as the ACMC, was the first mining enterprise in the state.

The miners in the 19th century entered the mines equipped with tools that included shovels, pry bars, breast augers, saws, axes, as well as temping bars.

In the early days, the owners of the mines provided this equipment, but financed them against the miner’s future wages.

Their food was provided on three-tiered dinner buckets that included drinking water, and their kerosene oil lamps provided lighting.

However, this lighting was very dim and smoky, and by the turn of the century, they were replaced with carbine lamps.

Although these provided better lighting for the miners, they were dangerous because of their open flame, and they were replaced in the 1930’s and 40’s with battery powered lamps.

In these early days, the miners would remove the coal in a four step process that included undercutting, drilling, blasting, and then loading.

The miners would blast the coal from the seam with small black powder charges, and once blasted out, they returned to the face to shovel out the coal.

They would shovel the lumps of coal into either trams or cars, and once loaded, mules would pull the loads along tracks where wire ropes or cables hosted them to the main entrance of the mine.

This process in the early days of hand loading was called the “room and pillar” method, and was used until the 1930’s and the introduction of mechanical loaders.

This process would later be replaced by Longwall mining to get the Coal in Alabama, and was facilitated by the mechanical continuous miner.

This enabled the mass extraction of this precious resource, along a lengthy front.

However, it was not considered to be very safe by most miners, as they preferred the ‘short wall method”.

This method used machinery to work a large portion of the coal face, but limited the span to a 150-foot front.

It was slower than the Longwall method, but again, was considered safer.

Alabama Coal

Alabama CoalImprovements to Mining Coal in Alabama

As time advanced and mechanization improved, surface mining begins to replace underground mining.

Strip mining, which was a variation of the open pit process, used bucket-wheel excavations to remove up to 200 cubic yards of dirt and rock, in just one bucketful.

Mining operations changed dramatically with the arrival of an English mining engineer, Joseph Squire.

He arrived in the state in 1859 and settled in Montevallo.

He used practical experience, exploration, testing, charting, as well as mapping, to help to identify seams and solve developing problems.

For the next 50 years Mr. Squire and an associate, William Gould, became central figures in the development of Coal in Alabama.

Their methods followed the patterns in other coal regions, where they used drift, shaft, and slope mining as their methods.

With drift mining, the miners would dig outcroppings and followed coal seams along a relatively level path.

This method of mining was very easy to navigate but had one major issue; it produced very little coal.

Slope mining had deeper shafts, but also have access to this natural resource closer to the surface.

By contrast, vertical shaft mines would feature elevators and allowed the miners to tap into deeper seams, but because of the ease of access, slope mining was the most popular.

With the onset of the Civil War, the mining of Coal in Alabama was absolutely devastated in 1865, by a series of Union Cavalry raids.

Most of the mines in the state lay dormant until the 1870’s, as the state began to recover.

These mines would eventually feed the Birmingham iron industry, and once again, began to boom.

When the L&N railroad was completed and linked Nashville and the Gulf of Mexico, Jones Valley, known for its rich deposits of coal, iron ore, and limestone, exploded, and the city of Birmingham became known as the “Magic City”.

Modern Coal Mining in Alabama

Modern Coal Mining in AlabamaCompany Towns

As the Coal in Alabama production increased, mining companies started to build thriving communities around their operations.

They were centrally located, had a company store, and provided a gathering place that was common for the residents of the town.

These towns had homes for the families of the workers, boarding houses, as well as several stores to shop in.

A stable social order was also provided by the addition of churches, schools, as well as fraternal organizations that the workers and their families could enjoy.

They also provided entertainment for the residents that included boxing matches, baseball teams, community bands, as well as bicycle clubs which were very popular in those early day.

A lot of struggling local farmers migrated to these mining sites, in search of economic opportunities and a better life.

Coal in Alabama and its mining operations remained in high demand during both World Wars, because of the need for materials, especially steel.

However, by the 1950’s coal markets nationwide were in steep decline, and most of the mines located in the state closed.

However, the high-quality met coal that the state produces and ships to steelmakers around the globe have kept the industry alive and thriving in these current times.

The thermal coal it produces helps to fuel local manufactures, and as mentioned earlier, provides very high paying jobs in the state.

Even with all the challenges it has faced in its storied history and recent challenges such as environmental issues, Coal in Alabama is very much alive and well.

References

http://www.encyclopediaofalabama.org/article/h-1473

Little Known Facts About Alabama

Alabama Gift Store

Numerous Items for You and Your Family to Enjoy

See it here at the Gift Store

Copyright 2019-2023 Alabamabackroads.com

All Rights Reserved